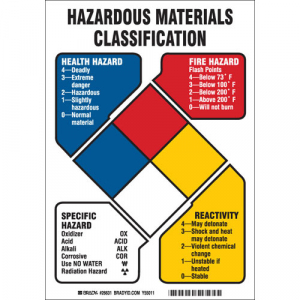

It may be a slow, natural process which only degrades the product without posing any safety hazards to the ship or the crew, or it may be a rapid, exothermic reaction evolving large amounts of heat and gases. Polymerisation generally results in the conversion of gases or liquids into viscous liquids or solids. Self-reaction: The most common form of self-reaction is polymerisation. Reactivity of various noxious liquid chemicals.But if there is too little or too much vapour compared to the air, so that the vapour-and-air mixture is either too lean or too rich, it will not burn. Vapour given off by a flammable liquid will burn when ignited provided it is mixed with certain proportions of air, or more accurately with the oxygen in air. Hazards of vapour given off by a flammable liquid while carrying at sea.The amounts of exposure required to produce these results vary widely with the nature of the substance and the duration of exposure to it. Toxicity is the ability of a substance, when inhaled, ingested, or absorbed by the skin, to cause damage to living tissue, impairment of the central nervous system, severe illness or, in extreme cases, death. Toxicology and associated hazards onboard chemical tankers.Indirect heating of adjacent cargoes and bulkheads during hot water washing of adjacent In addition, care shall be taken to avoid Obtained from shippers when handling heated cargo. The maximum temperature of adjacent cargo permitted for each cargo to be loaded shall be Will be non-hazardous to ship or crew, but can impair the commercial quality of the cargo or render it unusable. In other cases, reaction with certain alloys Some materials may trigger a self-reaction within the product. Taken to ensure that no incompatible materials are used or introduced during maintenance (e.g. The materials used in construction of the cargo systems must be compatible with the cargo to be carried, and care must be Stowage, the master must use a recognised compatibility guide to ensure that cargoes stowed adjacent to each other are Tanks) and prevented from mixing by using separate loading, discharging and venting systems. Such cargoes should be stowed away from each other (not in adjacent

Some cargoes react dangerously with one another. Such cargoes can be either inhibitedīy an anti-oxidant or carried under inert conditions. Oxygen compounds (peroxides) which, if allowed to build up, could cause an explosion. That can damage equipment or tank materials, or can cause oxygen depletion.Ĭertain chemical cargoes, mostly ethers and aldehydes, may react with oxygen in air or in the chemical to form unstable

OtherĬargoes react with water in a slow way that poses no safety hazard, but the reaction may produce small amounts of chemicals

The most noticeable examples are the isocyanates such cargoes are carried under dry and inert condition. The action to be taken in case of a polymerisation situation occurring while the cargo is on board should be covered by theĬertain cargoes react with water in a way that could pose a danger to both the ship and its personnel. An inhibited cargo certificate should be provided to the ship before a cargo is carried.

0 kommentar(er)

0 kommentar(er)